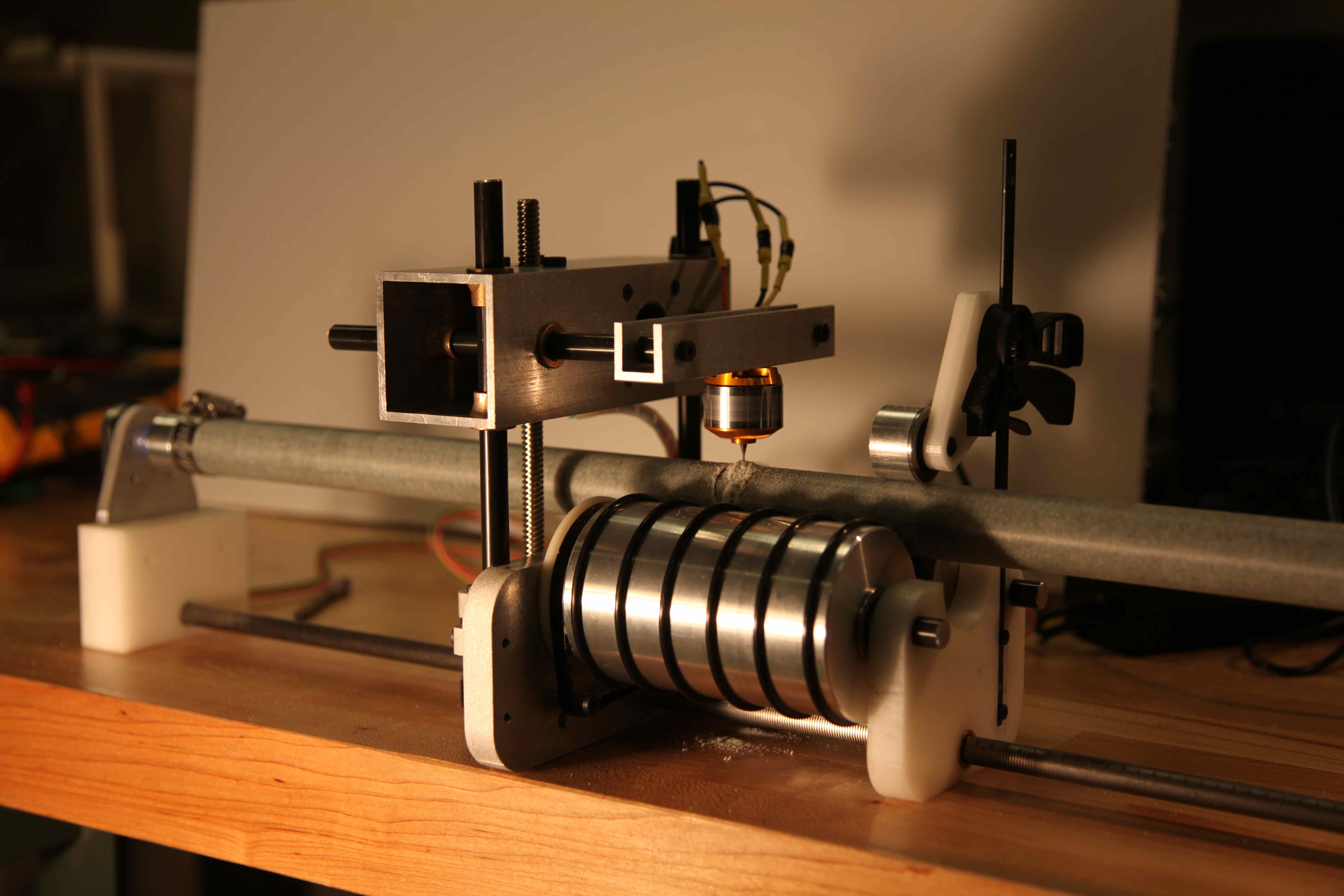

This mill shapes tube and rod stock to facilitate building three dimensional structures. It has a small working envelope (~3 inches of Y and Z travel, and tubes up to ~2 inches diameter) that can be positioned along the length of a tube up to 1 meter in length. A rotary encoder keeps track of angular position and a laser-scribed ruler sets position along the tube. In this way, we can have precision over a large area without the crazy costs of long linear motion systems.

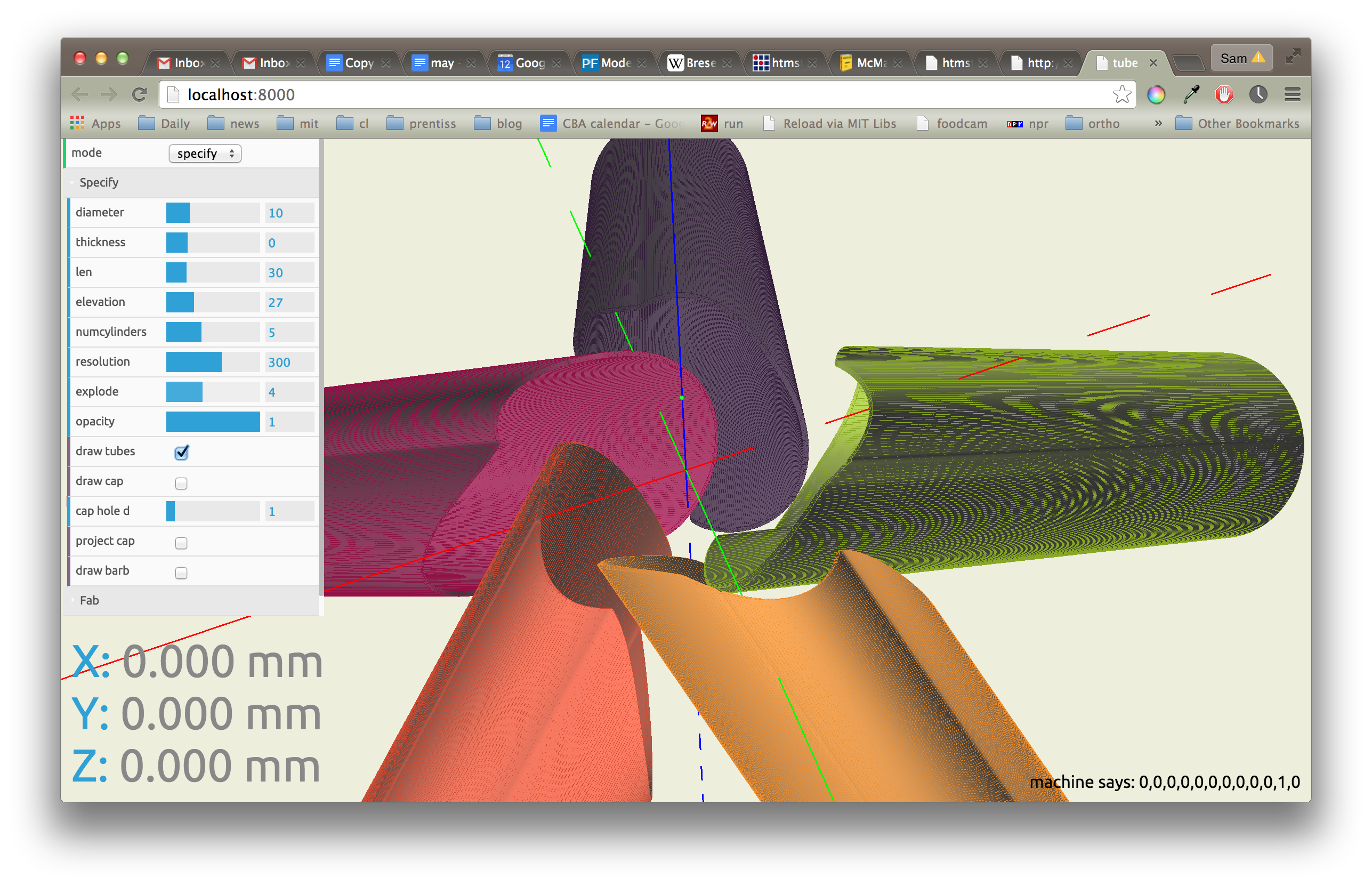

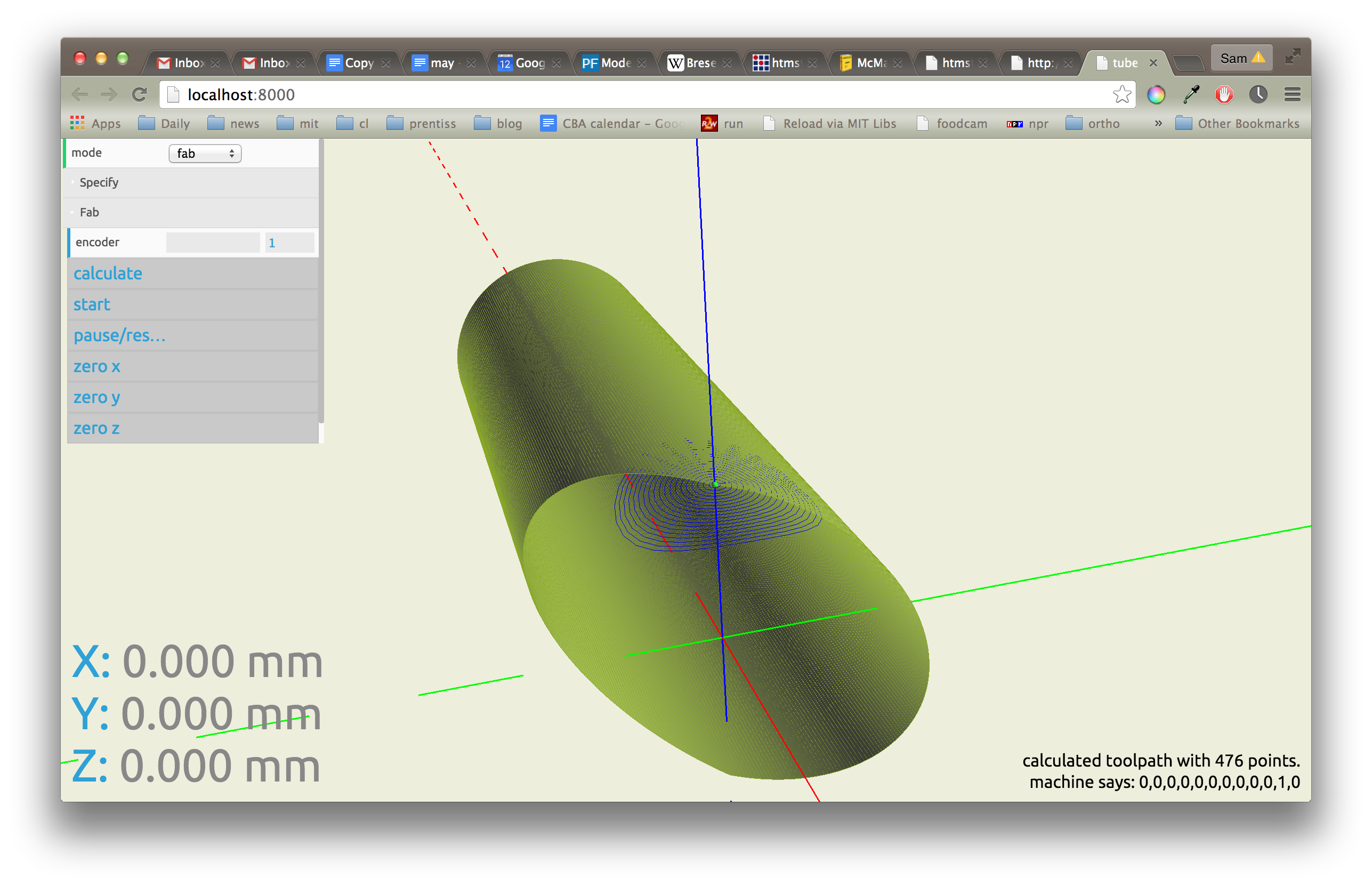

This machine is driven by a custom javascript interface that allows the user to design mating tube shapes and directly control the machine to produce them.

For now this page is mostly a placeholder – I hope to post more development soon.